Photo Gallery

Restoration Gallery

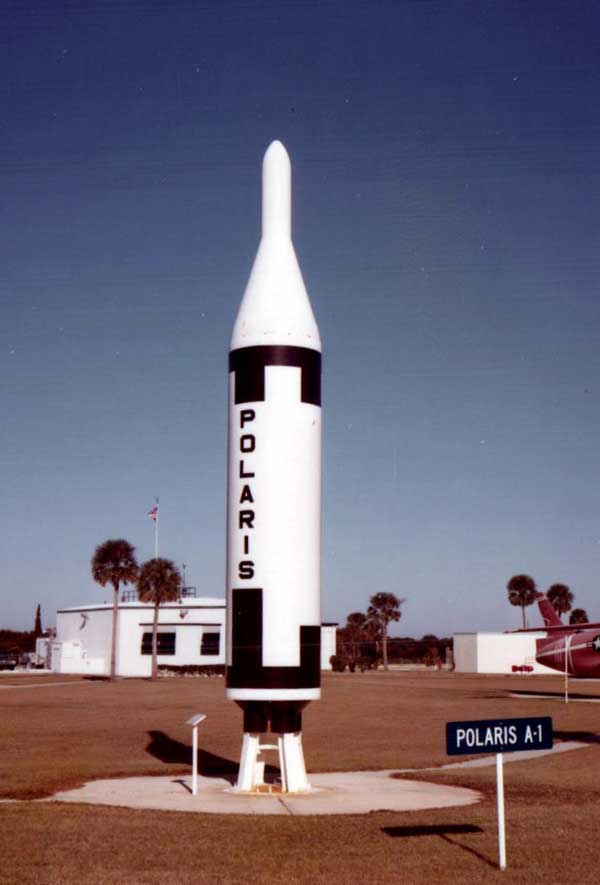

Overview

Display location:

- Hangar C, Cape Canaveral Space Force Station

Type: Fleet ballistic missile

Designation: UGM-27A

Payload: Nuclear warhead

Agency: U.S. Navy

Contractor: Lockheed Missile Systems Division

Cape Canaveral Space Force Station Operations: 1960-1963

History

Developed in the date 1950’s, the Polaris family provided the U.S. with its first submarine-based nuclear missiles. The first generation Polaris A1 became the ancestor of a missile family, which comprises the backbone of current U.S. nuclear offensive capability.

In 1955, the U.S. Navy and the U.S. Army (Army Ballistic Missile Agency) participated in a joint venture to create a sea-based version of the Jupiter IRBM. During the course of Jupiter testing, it became clear that the missile’s liquid fuels, especially volatile liquid oxygen, provided an unacceptable hazard during at-sea operations.

Naval Missile Research

The Navy, working with the Atlantic Research Corporation (ARC), was intrigued with the results of adding powdered metal to solid fuels. By adding large amounts of powdered aluminum to a fuel consisting of a mixture of arcite and ammonium perchlorate the ARC and Navy scientists observed a terrific jump upward in specific impulse. In this experiment, they hit upon the key to high-powered solid fuels.

Their findings ultimately contributed to the development of such new weapon systems as the Polaris Ballistic Missile Weapons System, the Air Force Minuteman ICBM and the Army Pershing Missile System. The introduction of a more powerful solid motor permitted the Navy to break off its involvement with the Army’s Jupiter liquid propellant motor and proceed on its own solid propellant program.

The need for a sea-based missile using solid fuel, lightweight construction, miniature inertial guidance, small nuclear devices and cold gas ejection form submarine tubes during uncertain environmental conditions provided considerable engineering challenges.

The Beginning of Polaris

With the highest military priority, Lockheed was assigned the task of developing the Polaris missile system. They selected Polyurethane Ammonium Perchlorate (PU/AP) solid fuel for the two-stage vehicle to eliminate the hazards associated with liquid fuels. In addition, a procedure for gas-propelled launching from submarine tubes was developed to eliminate the hazard of firing the missile’s first stage aboard ship.

Aerojet-General first and second stage engines were encased in a steel frame. The first stage engine had four rotary exhaust nozzles, while the second stage engine had one.

The missile’s MIT/GE/Hughes inertial guidance system was linked to a GE fire control system. A Westinghouse/MIT launch control system activated the high-pressure gas flow, which force the missile out of its launch tube.

Restoration

The Air Force Space and Missile Museum acquired the UGM-27A Polaris A-1 Fleet Ballistic Missile from the Naval Weapons Annex, U.S. Naval Ammunition Depot, Charleston, South Carolina in June 1965. The Polaris remained on display in the museum rocket garden until it was removed for restoration on 15 December 2005. The contract for the restoration project was awarded to Guard-Lee, Inc. of Apopka, Florida. After refurbishment, the Polaris was returned to Cape Canaveral Space Force Station on 9 May 2006.

Related Pages

- Polaris A3

- Polaris Archived Photography

- CCSFS Launch Complex 25

- CCSFS Launch Complex 29

- Sea Launches on the Eastern Range

- CCSFS HANGAR C