Photo Gallery

Blockhouse Overview

The blockhouse is similar to other structures built at Cape Canaveral Air Force Station in the mid 1950s. The walls are two-feet thick, and the dome-shaped roof varies from approximately five-feet thick along the edges to nearly eight-feet directly overhead.

The windows are composed of three segments of glass, each comprised of 15 layers of one-quarter inch glass, for a total of 45 layers of glass per window, measuring about one-foot thick. The double set of blast doors are made of heavy armor-like plating. This sturdy construction was to afford those working in the blockhouse (situated a mere 400 feet from the launch pads) with a measure of protection from an explosion.

Facility Interiors

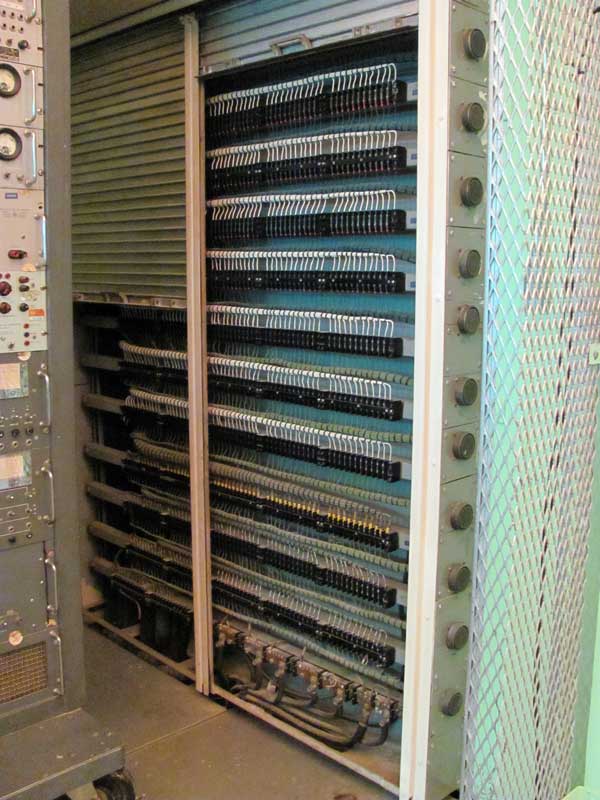

Launch Complex 26 is a dual-pad, single blockhouse facility. Two firing rooms are inside, one used in support of each pad, The firing rooms are furnished with much of the original equipment. The lighting fixtures, paint scheme, and wiring paths are all original. The gantry, or launch tower, is sitting on Pad 26B. Pad 26A is to the north.

Along the ground is a long row of metal plates which cover a three-foot deep cableway that connects the blockhouse and the launch pads. When this was an active launch complex, instrumentation on the gantry and missile was wired to controls in the firing rooms.

History

Construction of this facility began in 1956 to support the U.S. Army’s Redstone, Jupiter and Juno programs. The two pads were built at a cost of $3.4 million dollars each. Pad 26A supported its first launch 28 August 1957. Pad 25B’s first launch was 22 October 1957.

Explorer I, the first successful launch of an American satellite, occurred from Pad A on 31 January 1958. Three “monkeynauts” (Gordo, Able, and Miss Baker), were launched from here in 1958 and 1959, paving the way for future manned space flights.

The launch complex was deactivated in 1963 after a total of 36 launches. In 1964 the facility was designated for use as a space museum.

Related Pages:

- Launch Complex 26 Gantry Exhibit

- Launch Complex 26 Launch Pads Exhibit

- Launch Complex 26 Information Kiosk

- CCSFS Launch Complex 26

- USAF Space and Missile Museum

- Bioflights Exhibit

- Early Satellites Display

- Explorer I Exhibit

- Jeannie at the Museum Display

- Women in Space Display